Replacement Tillers

Making a replacement tiller.

General:

The Corribee tiller is made from one piece of timber, usually iroko. A replacement can be made in the same way, with relatively simple hand tools (plane, spokeshave, chisels, glasspaper etc). A jigsaw, router and random orbital sander would speed the shaping process. If you have access to machinery, a bandsaw in particular, the work is much easier and quicker.

With more work a laminated replacement is possible – you need accurately planed laminates around 6 to 8mm thick, epoxy resin, plenty of cramps and a jig to glue the laminates into the correct shape. Once the assembled stack of laminates are bonded the shaping can be done exactly as for a solid timber version, although some of the shaping is achieved in the process of laminating of course.

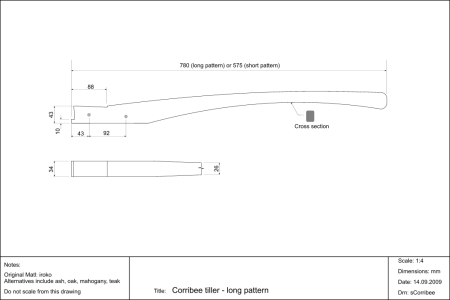

The drawing below can be printed and used as a template – click the link to enlarge the image, print out and stick the pages together.

The photo below shows a suitable laminating jig in use – blocks screwed to a stout board and polythene to prevent the work ending up bonded permanently to the jig!

Suitable timbers are (in order of durability) – Teak, iroko, English or european oak, mahogany and ash. Softwood can also be used – European redwood, larch and spruce are reasonably durable because of the resin content.

Maintenance:

As with all exterior woodwork, maintenance is needed to preserve the new look. Teak and iroko can be left to weather, but for a long life regular (6 monthly) coats of oil or varnish may be needed. A tiller cover will make a huge difference and is strongly recommended.

Detail of the stock end is shown here, with the two clearance holes for the 6mm dia bolts.

A couple of laminated tillers, the short pattern is mahogany/spruce and the long pattern is English oak/spruce:

Leave a comment